products Customized Chemical Processing Solution

-

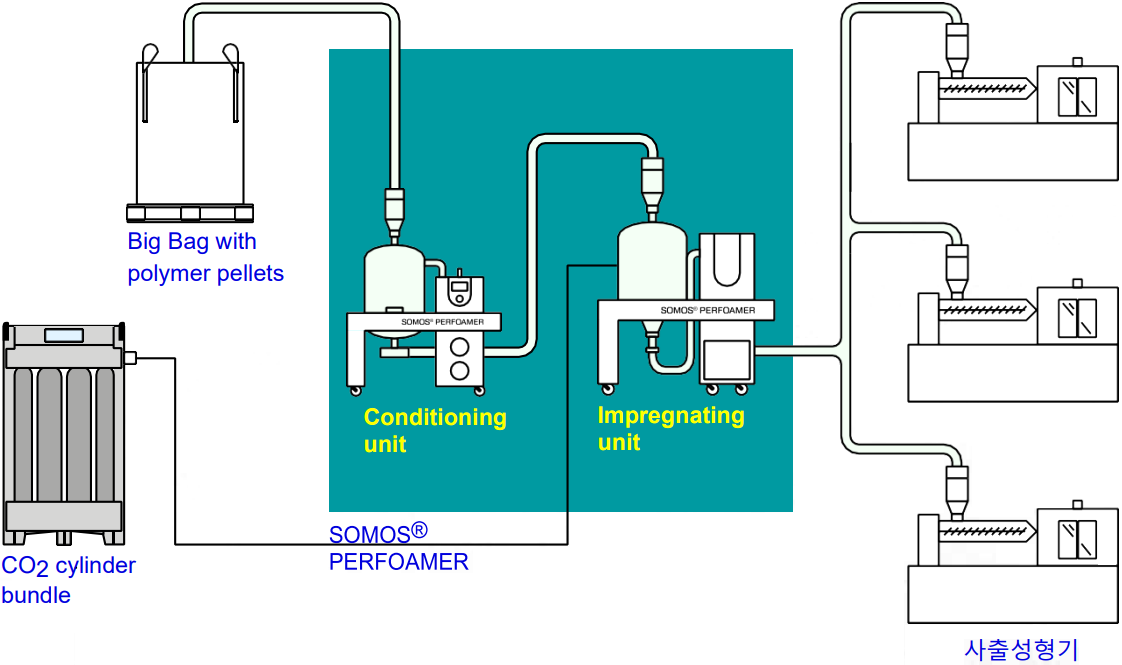

미세발포장치SOMOS® PERFOAMER

The innovative manufacturing solution for physical foaming

카탈로그 다운로드

원료 사용량 감소, 낮은 투자비용, 모든 사출기 및 다양한 원료에 적용 가능, 상용 폴리머 대비 60% 감량

Physical foaming with SOMOS® PERFOAMER초임계 이산화탄소를 이용한 물리적 발포

The PLASTINUM® 발포사출장치는 사출공정에서 화학적 발포와 물리적 발포를 결합한다.

발포 플라스틱 부품은 중량, 재료비를 줄입니다.

예전보다 더 많은 용도에 있어서 경량화와 동시에 튼튼한 부품의 수요가 늘어나고 있습니다. 발포 부품은 재료 사용량 감소에 의해 생산 코스트를 절감할 수 있도록 해줍니다. 이것은 자동차, 전자, 제약, 스포츠 레저 등의 많은 분야에서 아주 중대한 이점입니다.

발포 공정은 특히 사출성형의 중량을 줄이는데 효과적이며, 동시에 발포 원료는 낮은 점도 덕분에 가공이 빠르고 쉬워집니다. 게다가, 많은 플라스틱들에 있어서 발포가 이방수축(anisotropic shrinkage)을 줄여 줌으로써 전통적인 사출보다 더 나은 형태 재생을 가능케 합니다. 결과적으로 낮은 응력, 치수 안정성, 우수한 방음, 보온성을 가지게 됩니다.

The innovative SOMOS® PERFOAMER간단한 다목적 솔루션

- 상당한 원료 절감 효과 (원료 사용량 감소)SOMOS® PERFOAMER를 사용하면 얇은 제품에서도 우수한 발포가 가능해서 상당한 원료 사용량의 감소를 가져다줍니다. 그 결과 PC에서는 60%, GF30에서는 16%, 광물강화PP에서는 37%까지 사용량을 줄일 수 있습니다. (아래 표 참조)

- 높은 생산성게다가, 펠렛의 CO2 성분이, 가공할 폴리머의 점도를 낮추어 유동성을 증가시킴으로써 훨씬 빨리 사출되고 생산을 가속시켜 사이클타임을 줄여줍니다.

- 낮은 투자비기존의 조밀한 사출에 비해, 낮은 주형충진(mold filling) 압력이 필요하므로 실제 낮은 보압(holding pressure)이 사용됩니다. 그 결과 작은 사출기와 금형 사용이 가능합니다.

- 모든 사출기에 적용 가능함사용자들은 모든 사출기에서 SOMOS® PERFOAMER 의 간단한 취급과 다양한 적용 이점을 가질 수 있습니다. 통상 설비라는 것은, 새로운 타입으로 전환 시 비용이 들지만, 이 경우는 새로운 스크류, 사출기, 배압조절기가 필요 없이 단지 차단 노즐 또는 스크류 위치조절장치(screw position controller)가 권장 사항일 뿐입니다.

- 다양한 원료에 적용 가능실제로 바이오 플라스틱, 엔지니어링 플라스틱, 부러지기 쉬운 열가소성수지 및 복합수지 등 모든 수지에 적용 가능합니다. 만약 아주 높은 표면품질이 요구될 경우, 가스 역압(counter- pressure)과 같은 추가 단계를 거쳐 달성될 수 있습니다.

- 감량 효과(Weight reduction)이 새로운 기술로 인해 기존 상용 폴리머 대비 최대 60%의 감량을 달성할 수 있다.

Weight reduction for selected polymers *

| Polymer | Compact [g] | Foamed [g] | Reduction [%] |

|---|---|---|---|

| PC | 25,6 | 10,2 | 60 |

| ABS | 24,8 | 19,2 | 23 |

| PA GF30 | 31,9 | 26,9 | 16 |

| PP | 22,8 | 14,4 | 37 |

| TPE | 28,5 | 20,9 | 26 |

| PLA | 35,4 | 30,6 | 14 |

| PTT GF15 | 33,6 | 30,7 | 9 |

- * Production optimized for maximum weightreduction (weight reductions can vary)

- Source: Kunststoff-Institut Ludenscheid

modular and Industry 4.0 capable

일단 CO2를 주입하면, 수지 펠렛은 수지의 종류에 따라 긴 시간동안 가공 가능한 상태로 유지됩니다. SOMOS® PERFOAMER는 컨디셔닝 유닛, 주입장치, 가압 처리기로 이루어집니다. 컨디셔닝 유닛은 처리전의 수지와 CO2를 최적의 상태로 주입장치에 투입합니다. 이 공정은 일정한 품질을 유지시켜주는 PLC controller에 의해 진행됩니다.

운전은 터치스크린으로 진행됩니다. SOMOS® PERFOAMER는 상위 컨트롤 시스템에 통합도 가능합니다. SOMOS® PERFOAMER에는 CO2 가 주입된 펠릿을 저장하는 250리터의 buffer tank가 있다. SOMOS® PERFOAMER에서 나오는 수량은 여러 사출기로 배분될 수 있습니다. 소재에 따라 최대 시간당 60Kg까지 공급 가능합니다.

Output volume as a function of material

| Polymer | Bulk density [kg/l] | Process time [h] | Output volume [kg/h] |

|---|---|---|---|

| PC | 0,74 | 2,5 | 59 |

| PA6 * | 0,70 | 5,0 | 28 |

| PP | 0,56 | 2,5 | 45 |

| ABS | 0,70 | 2,5 | 52 |

| PLA (cryst.) * | 0,80 | 6,0 | 27 |

| TPE | 0,72 | 2,5 | 58 |

- * If need be, output volumes can be significantly increased by predrying

- Source: ProTec Polymer Processing

LeftPressure conveying shut-off valve on the impregnating unit

Center leftExhaust elbow on conditioning unit

Center rightElectrical connection for impregnating/conditioning unit

RightCO2 supply to impregnating unit